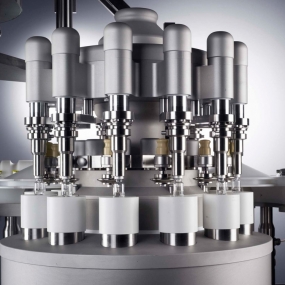

CAPSULE FILLING MACHINES (by Syntegon)

Syntegon capsule filling machines for powders, pellets, micro-tablets, liquids and combinations of these.

Syntegon capsule filling solutions comprise a set of dosing options including micro-dosing; they also include a high containment packaging solutions for the production of capsules with highly potent products.

These machines, along with checkweighers (by statistics or 100% checkweighing), are capable of automatically regulating product dosing to prevent weight deviations.

The variety of Syntegon GKF capsule filling machines, all of them of modular design complying with cGMP and CFR part 11 standards, ranges from low output or laboratory versions like the GKF 702 with a 3000 to 42,000 capsule/h output to the GKF 3000 with an output of 175,000 capsules/h.

Capsule checkweighers can be integrated into machines or operate as separate units:

- IPK – In-process control for statistical net checkweighing

- KKE – 100% checkweighing for outputs of up to 230,000 capsules/h

- KKX – 100% checkweighing and detection for internal capsule flaws and foreign particles through an X ray system, it outputs up to 220,000 capsules/h.

Syntegon capsule filling machine family includes a number of Capsylon models intended for filling capsules with powder, pellets or granules of nutriceutical products. The Capsylon model outputs range from 42,000 to 175,000 capsules/h.

Bosch KKX 3900: 100 per cent inspection via x-ray technology

FILLING AND SEALING OF STERILE PRODUCTS (by Syntegon)

Wide range of process specific equipment for filling and sealing sterile liquids in ampoules, vials, carpules and syringes, as well as for powder filling of vials.

The sterile product packaging machines offer CIP or SIP options, weighing stations, IPC, dosing through volumetric or time-pressure peristaltic pump, and are designed to comply with GMP and FDA standards.

All this equipment can be combined with solutions for container washing, depyrogenation tunnels, vial sealing, ring coding, crack inspection and detection units, as well as with isolation solutions (RABS, cRABS isolator) in order to make up complete primary packaging lines. The line could be completed with case packing, banding and cellophane sealing, boxing and palletizing machines by Pester PAC Automation.

Syringe Filling and Sealing Equipment

Machine models FLS for filling and sealing pre-filled plastic or glass syringes, with outputs of up to 18,000 units/h, filling volumes of 0.5 mL to 20 mL, and maximum syringe diameters of 30 mm.

Machine models FXS for filling and sealing nested syringes (up to 160 syringes per nest), with output rates from 5,400 to 57,600 units/h, and filling volumes of 0.5 mL to 20 mL (up to 50 mL as an option).

FXS Combi model for filling nested syringes: outputs of up to 11,300 units/h and filling volumes of 0.5 mL to 20 mL; vials: outputs of up to 8,800 units/h and filling volumes of 2 mL to 30 mL; and carpules: outputs of up to 7,000 units/h and available volumes of 1.5 mL to 3 mL.

We also offer the complementary units ABO and ATO for automatic bag and tray opening with performance rates of 6 bags/min, automatic USD syringe de-nester with performance rates up to 18,000 units/h, and rod insertion and labeling system, RIL.

Ampoule Filling and Sealing Machines

Lineal or rotary machines to suit production requirements with possibility to process open or closed ampoules.

AFG models for filling antibiotic powder into plastic or glass ampoules and vials, with outputs ranging from 7,6000 to 19,2000 units/h, and filling volumes between 2 mL and 250 mL.

ARF models for filling and sealing ampoules and vials in combination, with up to 7,200 units/h outputs and volumes of up to 30 mL for ampoules and 50 mL for vials.

ALF models for big scale productions with outputs of up to 30,000 units/h and ampoule filling volumes from 1 mL to 30 mL.

Carpule Filling and Sealing Machines

Filling and sealing MRD and MLF models for with maximum outputs of 36,000 units/h and capable of processing carpules with 8.65 mm to 24 mm diameters and up to 70 mm high.

The transference system ensures container safety as well as accuracy of positioning, filling (precise filling sensor by laser) and sealing.

Vial Filling and Capping Machines

MHI model for filling and capping vials destined for clinical trials, with outputs of up to 3,600 units/h, filling volumes of 2 mL to 100 mL, and capacity for vial diameters of 16 mm to 52 mm.

MLF models for medium scale productions with outputs of 7,200 to 24,000 units/h, filling volumes of 2 mL to 500 mL, and capacity for vial diameters between 14 mm and 86 mm. They feature an integrated capping station. Maximum vial height of 180 mm.

FLC models for outputs of 36,000 units/h, filling volumes of 2 mL to 500 mL, and capacity for vial diameters of up to 86 mm. Maximum vial height of 180 mm.

MRF models for filling and sealing vials, screw-cap bottles and bottles with stoppers and spout inserts. Performance rates of up to 3,600 units/h, filling volumes of 2 mL to 500 mL, and container diameters between 16 mm and 86 mm. Maximum vial height of 180 mm.

VRT and VRK machines for vial capping at outputs of up to 36,000 units/h, filling volumes of 2 mL to 500 mL, capacity for maximum container diameter of 86 mm, and cap diameters between 13 mm to 32 mm. Maximum vial height of 180 mm.

RABS and cRABS Isolation Solutions

All Bosch sterile product filling equipment can be executed with RABS and cRABS isolation systems (RABS system in sealed chamber with airflow) and with isolators for highly potent products in aseptic conditions.

“Single-use” Dosing of Sterile Products

Single-use dosing system by Syntegon PreVAS (co-designed with Sartorius), validation, assembly and sterilization for liquids dosing in injectable lines. This system can be combined with volumetric and time-pressure peristaltic pumps.

PHARMACEUTICAL CONTAINER WASHERS AND STERILIZATION TUNNELS (by Syntegon)

Syntegon washing machines for pharmaceutical containers such as bottles, vials, syringes, carpules and ampoules; to be used in sterile product filling. These machines in conjunction with container sterilization tunnels and Bosch sterile product filling lines provide comprehensive solutions for primary packaging. Following the ultrasonic bath in water, the container is passed through a cleaning station with pure water (WFI) and processed air.

The RRU and RRN washers’ capacity varies according to container sizes:

Up to 36,000 units/h for ampoules of 5 mL to 30 mL.

Up to 36,000 units/h for vials 15 mL to 1,000 mL.

Up to 24,000 units/h for syringes of up to 20 mL.

Up to 42,000 units/h for carpules of up to 10 mL.

Exiting the washing station, the containers are directed to a Syntegon HQL sterilization and depyrogenation tunnel by dry heat. The tunnels consist of a loading zone, heat module, splitter, sterilization and finally a container cooling module. Syntegon can provide different module sizes depending on the required capacities.

INSPECTION EQUIPMENT (by Syntegon)

Syntegon equipment intended for the detection of foreign particles and cosmetic flaws in ampoules and vials, and for the inspection of cracks in ampoules, vials, carpules and syringes caused by high pressure.

AIM equipment for inspection of particles and flaws through camera vision, with checking performance of up to 600 units/min of containers with a maximum diameter of 65 mm.

KHS equipment for container integrity inspection (cracks) by a spectroscopic laser technology used for vacuum filled and gas purged lyophilized products. It is capable of checking up to 600 units/min of containers with a maximum diameter of 85 mm.

KLD equipment for crack detection in ampoules, vials, syringes and carpules through a high voltage technology with performance rates of up to 600 units/min of containers with a maximum diameter of 52 mm.

Syntegon also provides semi-automatic solutions, VIs, Etac Easy View for small batch processing.

AUTO-INJECTOR ASSEMBLY (by Syntegon)

Syntegon Moëller Devicon designs and manufactures manual, semi-automatic and fully automatic equipment for auto-injector assemblies.

The modular design of this equipment allows the addition of assembly stations in order to increase output.

The manual model MMA has an assembly performance of 3 to 5 units/min.

The semi-automatic model MSA is capable of assembling 5 to 15 units/min.

The fully automatic model MRA (rotary) has an output of 100 units/min, while the MLA (lineal) can assemble up to 200 units/min.

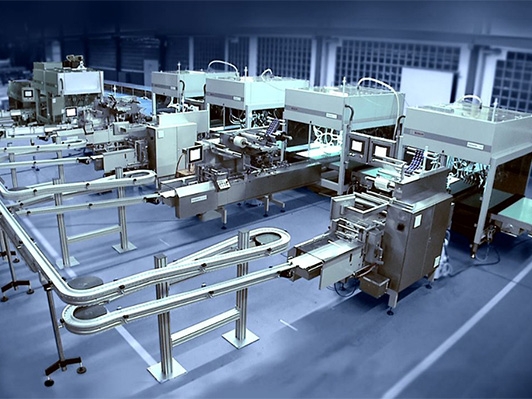

FILLING AND STOPPING LINES (by Syntegon)

Syntegon combined filling and stop inserting lines for oral syrup ophthalmologic products. These machines are executed in lineal and rotary versions with options for CIP and SIP.

Lineal and rotary filling machines by Syntegon with outputs of up to 400 bottles/min and dosing range between 50 mL and 1.000 mL.

Syntegon intermittent rotary stopper insertion machines with outputs between 60 and 400 bottles/min.

Stopper and closure types: pressure closure, screw stopper and dispensing closure.

SOLID AND SEMI-SOLID PACKAGING (by Syntegon)

Vertical Solutions

Machines for all kinds of pharmaceutical powders, pellets and granules: vitamins, analgesics, soluble drugs, etc.

Syntegon sachet filling machines can reach outputs of 125 sachets/min for single, double or chain sachet formats.

Maximum sachet size: 50 mm-100 mm wide, 55 mm-150 mm long.

Maximum stick pack size: 28 mm-45 mm wide, 60 mm-180 mm long.

It features a 100% checkweighing system, and can be equipped with a case packing system.

Sachet case maximum size: 102 mm wide x 240 mm long x 13 mm high.

Stick pack case maximum size: 85 mm wide x 150 mm long x 160 mm high.

Horizontal Solutions

HDG machines for primary and secondary packaging in reel fed pre-formed bags and sachets for packing plastic ampoules, lens, powders, semi-solids, etc.

Available bag formats: pillow, corner-sealed, 4 sided seal, 3 sided seal, Doy, bag chain, flat bottom and with special contours. All these formats with options for easy opening features, eurohole, round hole and spout.

Outputs: 60-400 bags/min

Bag sizes: 40 mm-400 mm wide, 40 mm-400 mm long

Horizontal solutions

HDG solutions for primary and secondary packaging in preformed pouches or from coils such as: plastic ampoules, lenses, powdered products, etc.

Available pouch designs: cushion, sealed edges, 4-sided sealing, 3-sided sealing, flat bottom, Doy type, pouch chain and with special shapes. All of them are available with optional holes, easy-openings, euroholes and spouts.

BFK

Capacidad: 60 pouches/min from preformed pouches

Pouch size: 80-200 mm (W), 100-400 mm (L)

RBK

Capacity: 90 to 240 pouches/min from a coil

Pouch size: 40-200 mm (W), 40-400 mm (L)

RBG

Capacity: from 90 to 300 pouches/min from a coil

Pouch size: 40-300 mm (W), 40-400 mm (L)

RBXG

Capacity: 90 to 400 pouches/min from a coil

Pouch size: 40-400 mm (W), 40-400 mm (L)

VERTICAL PACKAGING (by Syntegon)

Wide variety of solutions according to bag size and design.

Outputs of Syntegon vertical packaging machines: up to 240 bags/min.

Bag formats: pillow, corner-sealed, flat bottom, 3 sided seal, 4 sided seal, 3 sided seal zip and Doy zip.

Maximum bag dimensions: 400 mm wide, 700 mm long.

All machines can accommodate options for round hole, eurohole, easy opening features, zip closure system, and ultrasonic sealing.

FLOW-PACK PACKAGING (by Syntegon)

Syntegon Tevofarm machines (medium output range) and Syntegon machines (high output range) for primary and secondary packaging of pharmaceutical products like blisters, syringes, vials, etc. Thanks to Syntegon robotic handling and boxing or case packing systems, a comprehensive packaging line can be conformed.

The output performance of Syntegon Tevopharm machines can reach a maximum of 200 units/min (at 80 m/s), while Syntegon machines can output up to 1,500 units/min, and can be executed in versions with wash-down features and air-tight seals for IV bags, single-dose, blisters, syringes, ophthalmologic products, protective locking trays, as well as re-close and easy opening features.

Pack 401 Horizontal Flow Wrapper

Syntegon Pack 401 flow wrapper with Pack Feeder 4 inline feeder

Seamless System for the Primary and Secondary Packaging of Bar Products

BAG SEALING AND CLOSING (by Syntegon)

Bag sealing and closing equipment from Syntegon’s Doboy division for bags of paper, thermoplastics, sterile medical film – Tyvek, Mylar, etc. – and polypropylene. These machines are used for sealing bags with solid and/or liquid pharmaceuticals, medical devices, active ingredients in bulk, etc.

The modular standard machines can be adapted to the customer’s requirements for vertical or horizontal sealing, counting systems, conveying belts, ink codification solutions, etc.

All Syntegon Doboy’s machines are designed to ensure a hermetic and tight seal and the process can be validated and qualified in accordance to FDA regulations.

The sealing and closing machines can perform a range of speeds from 100 to 1.200 inches/minute and the sealing area width can vary according to the customer’s request or the product’s needs.

The high-speed machine for polypropylene bags can reach a maximum speed of 45 metres/minute.

Bag sealing and closing stand up machine Syntegon Doboy B550

Bag sealing and closing stand up machine Syntegon Doboy MVI 0111

Performance demonstration of the bas sealing and closing Syntegon Doboy machine

HANDLING AND ROBOTIC SYSTEMS (by Syntegon)

Modular, flexible and extendable Delta robotic systems for automation and handling of all kinds of cosmetic products like sachets, flow-packs or pouches that are fed into boxing, case packing or blistering lines.

Syntegon offers countless gripper options to suit production needs and customer requirements of product handling.

These machines have handling performances of up to 2,200 products/min featuring multiple cells with 3 robots each.

DELFI

Capacity: handles up to 2,200 units/min with 3 delta robots per cell and multiple cells.

Suitable for product grouping towards flowpack packaging lines.

PALOMA

Capacity: handles up to 400 units/min with 4 delta robots per cell. Different cells are combinable.

Suitable for top loader feeder for packed products moving towards secondary packaging lines and cartoning.

PRESTO

Capacity: handles up to 600 units/min with dual flow. Different cells are combinable.

Suitable for product grouping from flowpack packaging equipment and feeding moving towards secondary packaging and/or cartoning production line.

ASTOR

Capacity: handles up to 1.000 units/min with 8 robots. Different cells are combinable.

Suitable for product provision towards blisters.

Syntegon Pick and Place Robotics

Module ++ automated biscuit packaging line with Delta robots and horizontal flow wrappers

VFFS Packaging Line Featuring Delta Robotic Case Packing

CASE PACKING MACHINES (by Syntegon)

Medium to high performance machines for case packing sachets, ampoules on trays with leaflets, flasks, bottles, flowpacks, tubes, vials, syringes, blisters, stick packs etc.

These machines can be combined with checkweighing systems, vertical and horizontal packaging machines and flow-pack systems.

They are capable of processing multiple case formats like tray, tray + lid, trays with display effects, and they provide different gripper options for product handling.

Outputs: up to 240 cases/min of minimum and maximum sizes (length x width x height): 20-600 mm x 15-400 mm x 25-400 mm

Modular and flexible: Syntegon CUT 1405 horizontal cartoning machine

Syntegon line for eyedrops

Syntegon CFC 2012 horizontal cartoning machine for large scale formats

High performance and top loader solutions

Syntegon equipment (TTM model) for sachet cartoning, syringes or ampoules onto trays including leaflets, etc.

Multiple case designs: tray, tray+cover, display type, etc. and optional clamps for product handling.

Capacity: 30 to 150 cases/min and up to 1,000 units/min

Minimum and maximum case sizes (L x W x H): 100-600 mm x 100-400 mm x 25-400 mm

FILM WRAPPING (by Pester Pac Automation)

Balcony-like designed machines for banding and cellophane sealing pharmaceutical products (individually or grouped) such as vials, blisters, syringes, bottles, inhalers, tubes, cases, etc.

Pester Pac Automation machines stand out for their ergonomic design (GMP compliant), high quality and intuitive easy operation logic.

Pewo-Pack models are ideal for product banding and wrapping with polyethylene. The maximum performance for cases is 60 cycles/min, with maximum case dimensions of 400 mm x 400 mm x 250 mm. For bottles, performance rates may reach 50 cycles/min with 300 mm x 300 mm x 250 mm dimensions.

Meanwhile, the Pewo-fold equipment line is adequate for wrapping operations with OPP, PVC, cellophane and polyethylene; these machines reach performances of up to 60 cycles/min for format sizes of 400 mm x 350 mm x 140 mm.

VERTICAL AND HORIZONTAL CASE PACKING (by Pester Pac Automation)

Pester Pac Automation provides two boxing solutions for boxing pharmaceutical cases, bottles, flasks, sprays, tins and tubes, they provide different feeding and grouping options according to the product for trays, wrap-arounds and American box formats.

All Pester Pac Automation designs are GMP compliant and stand out for their ergonomic and compact design, accessibility and easy operation.

For horizontal boxing solutions, Pester provides the PEWO-form UVP boxing machines with output performance of up to 40 boxes/min (500 cases) for minimum box dimensions of 150 mm x 120 mm x 105 mm, and maximum box dimensions of 600 mm x 400 mm x 400 mm.

PEWO-form TLC are vertical boxing machines suitable for products that should be boxed by top loading robots; these products include bottles, jars, tubes, cases, shelf-ready containers, inhalers, vials, etc. The maximum output performance for the TLC machines is 60 boxes/min, dealing with minimum box dimensions of 200 mm x 120 mm x 100 mm, and maximum box dimensions of 600 mm x 400 mm x 400 mm.

PALLETIZING (by Pester Pac Automation)

Palletizing equipment using programmable anthropomorphic robots to handle a variety of box and patterns, which enables palleting of wrapped products, bottles, trays, etc.

Peter PEWO-Pal solutions include 1 to 5 station palletizers for all kind of pallets with a maximum height of 2,000 mm. PEWO-Pal machines have a maximum output performance of 12 cycles/min, and ensure a gentle product handling.

END OF LINE PACKAGING (by Pester Pac Automation)

Pester offers banding, cellophane wrapping, boxing (vertical and horizontal) and palleting comprehensive solutions to conform line ends for pharmaceutical and cosmetics products. These machines’ easy integration possibilities have helped develop modular and compact high performance cartoner-palletizers.

AGGREGATION AND TRACEABILITY (by Syntegon and Pester Pac Automation)

Syntegon CPS modular semi-automatic machines for “Tamper Evident” labeling, serialization (unique serial number printing), verification and aggregation of cases and pharmaceutical products featuring “Track & Trace” software. These stand-alone machines can be integrated into new or existing production lines.

Syntegon CPS machines output up to 400 cases/min for case dimensions between 20 mm x 10 mm x 50 mm and 125 mm x 125 mm x 260 mm.

Meanwhile, Pester Pac Automation also provides aggregation solutions for banding, wrapping, boxing and palleting equipment.

Printed, verified and sealed: Syntegon Track & Trace solutions

Track & Trace module: CPS 0300 Flatboard for offline serialization

Syntegon Track & Trace Solution

LABELLING (by Berning)

Sleeve y Tamper Evident

Berning machines can deal with a wide range of product diameters, 10 mm to 210 mm for sleeve, with performance rates between 80 and 600 cycles/min. Berning also offers machines with different performance rates for lineal horizontal sleeve labelling of vials, flasks, syringes, etc.; they feature a U design for product grouping.

FLAT PRODUCT FEEDING (by RonTech)

Stand-alone or integrated machines into packaging lines for aligning, separating and feeding flat products such as envelopes, leaflets, promotion fliers, etc.

The available systems are:

- Envelope feeding and positioning by friction, with outputs of up to 200 m/min for envelope sizes of: 40-320 mm x 50-300 mm x 2510 mm (width x length x height)

- Feeding by suction cup for the above specified sizes with outputs of up to 80 m/min.

- Rotary feeding with outputs of up to 200 units/min.

All feeders can be connected to a storage rack.

Spacefeeder aligning, separating and feeding machines for envelopes and flat bags 40-300 mm wide and 50-400 mm long, delivering outputs of up to 300 units/min.